FULUKE Mixing Tanks — Reliable Cosmetic Mixing Equipment

Product Overview

FULUKE mixing tanks are engineered mixing and emulsifying equipment designed to meet the production needs of cosmetics, food, pharmaceutical, and chemical manufacturers. Backed by Guangzhou Fuluke Cosmetic Equipment Co., Ltd.’s 30+ years of industry experience, these mixing tanks combine reliable mechanical design with sanitary construction to support GMP and ISO production standards.

Core Features

- Vacuum emulsifying capability for stable creams and lotions

- High-shear homogenization for uniform particle size and texture

- Sanitary stainless-steel construction with polished interiors for easy cleaning

- Temperature control and jacketed heating/cooling for precise processing

- Customizable sizes and mixing configurations to fit batch and continuous processes

Benefits for Manufacturers

Using FULUKE mixing tanks helps manufacturers improve product consistency, reduce processing time, and lower energy consumption. The design minimizes contamination risk and simplifies cleaning and validation—critical factors for GMP-compliant production lines.

Applications & Compatibility

FULUKE mixing tanks are ideal for producing creams, lotions, gels, sauces, and pharmaceutical suspensions. They integrate seamlessly with vacuum emulsifying mixers, homogenizers, and filling and sealing machines to form complete turnkey packaging lines—from ingredient preparation and emulsification to filling and final packaging.

Service & Support

FULUKE offers tailored engineering, automation control upgrades, and on-site commissioning. Global technical support includes start-up assistance, operator training, and long-term maintenance to ensure reliable operation and compliance with international hygiene standards.

Why Choose FULUKE

With a strong focus on innovation and quality, FULUKE mixing tanks deliver dependable performance and measurable production improvements. Based in Guangzhou, our teams combine engineering design, precision machining, and strict quality management to provide equipment you can trust. Contact us to discuss a customized mixing solution for your production needs.

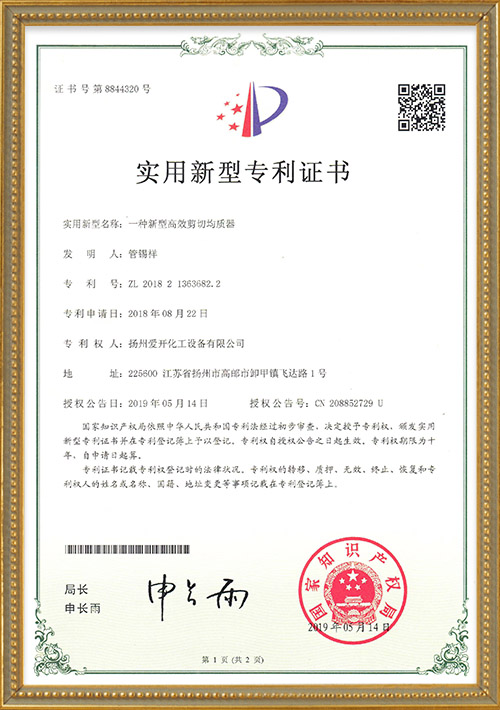

Our Certifications

Patent certificate

CE certificate

ISO certificate

Question you may concern

Can the water produced by an RO water purifier be drunk directly? Why?

The water produced by a qualified RO water purifier (i.e., "purified water") is generally drinkable directly.

This is because the high-precision filtration of the RO membrane removes harmful microorganisms (bacteria, viruses), heavy metals, pesticide residues, and other contaminants from the raw water, resulting in a water quality that meets the requirements for direct drinking. However, it is important to regularly replace the filter cartridge to ensure proper operation of the device.

If the liquid is still turbid after filtration, what could be the cause?

Common causes include: ① Insufficient freezing (low temperature or too short a freezing time); ② Clogged filter element or overly large pore size; ③ Uneven material flow leading to insufficient localized condensation. Solution: Extend the freezing time, replace the 0.1μm precision filter element, check the pipes for blockage, and optimize flow control.

We want to fill products in multiple volumes (e.g., 100ml, 250ml, 500ml). Do we need to purchase multiple filling machines?

No, most automatic filling machines support multiple volume adjustments. When purchasing, please confirm the machine's "volume adjustment range" (e.g., 50ml-2000ml) to ensure it covers your desired specifications. Changing volumes simply requires modifying the fill volume parameters on the touchscreen. If the volume difference is significant (e.g., from 100ml to 1000ml), minor adjustments to the filling head height or feed rate may be necessary, without replacing the machine.

Can you customize the machine?

Of course, we provide customized services according to customer needs.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

You May Also Like

Stainless Steel Mixer Liquid Mixing tank with Agitator Homogenizing Mixing tank Vacuum Sealed Mixer Machine

Flip Cover Multi-function Liquid Wash Mixing Tank Blender Liquid Detergent Mixer Homogenization Stirring Tank

Polypropylene PP Mixing Tank Anti-Corrosion Mixer Reaction Kettle with Agitator Chemical Mixing Vessel

Facebook

Instagram

YouTube