FULUKE Stainless Mixing Tank — Hygienic Mixing for Cosmetics

Overview

FULUKE (Guangzhou Fuluke Cosmetic Equipment Co., Ltd.) brings over 30 years of experience to our stainless mixing tank. Designed for cosmetics, food, pharmaceutical and chemical production, this tank combines sanitary construction, reliable agitation and flexible control to ensure consistent product quality and safe, efficient manufacturing.

Key Features

Construction and Materials

Built from high-quality stainless steel (SS304 or SS316L), the tank features polished interior surfaces, sanitary welds and a robust frame. Mirror-polished finishes reduce product adhesion and make cleaning simple. All contact parts meet international hygiene standards for safe production.

Mixing, Heating and Vacuum

Multiple agitator options (anchor, propeller, turbine) ensure gentle to high-shear mixing depending on your formula. The jacketed design supports heating or cooling with steam, hot oil or glycol. Optional vacuum capability removes trapped air and helps degassing for smoother creams and lotions.

Control, Cleaning and Maintenance

PLC touch-screen controls provide precise speed, temperature and mixing profiles. CIP (Clean-In-Place) systems and easily accessible manways simplify cleaning and shorten downtime. Modular components and standardized sealing make maintenance quick and cost-effective.

Quality and Compliance

Engineered to meet GMP and ISO standards, FULUKE tanks deliver traceability, material certificates and documentation. Sanitary design minimizes contamination risk, and optional validation support is available for regulated industries.

Benefits

- Stable, repeatable batches for consistent product quality

- Fast heating and efficient mixing that saves time and energy

- Hygienic design reduces contamination risk and eases cleaning

- Customizable to production scale and formula requirements

- Strong after-sales support including installation and training

Applications

Ideal for creams, lotions, serums, gels, sauces and more in cosmetics, food, pharma and chemical lines.

Why Choose FULUKE

With three decades of expertise in mixing and emulsifying equipment, FULUKE offers tailored solutions, reliable manufacturing and global service. Our stainless mixing tanks are engineered to improve efficiency, ensure batch consistency and support safe, scalable production.

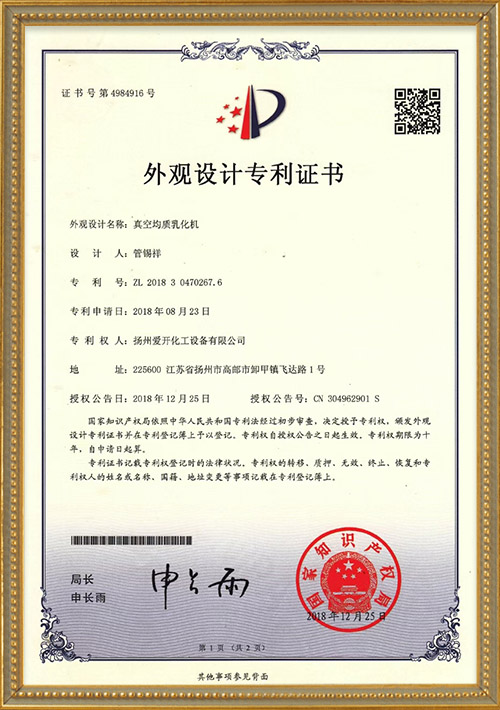

Certificate display

ISO certificate

Patent certificate

Certificate of conformity

Question you may concern

What industries is the vacuum emulsifier suitable for?

It is widely applicable to the production needs of creams, lotions, gels, ointments, etc. in the cosmetics, pharmaceutical, food, chemical and other industries.

What should I check before daily use of a storage tank?

Inspect the tank for signs of deformation or leakage, and check that the sealing components are intact.

Confirm that the level gauge, pressure gauge, and other instruments are displaying normal readings and that the valves are opening and closing freely.

If storing flammable or explosive media, check that the anti-static device is effective.

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

You May Also Like

Stainless Steel Mixer Liquid Mixing tank with Agitator Homogenizing Mixing tank Vacuum Sealed Mixer Machine

Flip Cover Multi-function Liquid Wash Mixing Tank Blender Liquid Detergent Mixer Homogenization Stirring Tank

Facebook

Instagram

YouTube