FULUKE Stainless Steel Mixing Tank with Agitator

Overview

The FULUKE Stainless Steel Mixing Tank with Agitator is a durable, sanitary solution designed for stable, repeatable mixing of creams, lotions, sauces and other liquid or semi-solid products. Constructed from high-quality 304/316 stainless steel and engineered for hygiene and safety, this tank supports manufacturers who need consistent product quality and efficient production.

Key Features

- Sanitary design: Smooth mirror-polished interior, rounded bottom, CIP-friendly surfaces for fast, effective cleaning.

- Stainless construction: Food- and cosmetic-grade 304 or 316 stainless steel to resist corrosion and meet hygiene standards.

- Jacketed heating/cooling: Even temperature control via steam, hot water, or glycol systems to handle melting, heating and cooling steps.

- Adjustable agitator: Anchor, propeller or turbine-style agitators with variable-speed drive for gentle blending or vigorous mixing as required.

- Reliable seals and safety: Mechanical seals, sanitary ports, pressure relief and safety interlocks to protect product and operators.

- Easy discharge: Sanitary butterfly or ball valve and bottom outlet for fast, complete product transfer.

Technical Specifications (Typical)

- Capacity range: Customizable from 50L to 10,000L

- Material: SS304 / SS316L

- Surface finish: Mirror-polished (≤ Ra0.4) interior

- Agitation: Variable speed motor, selectable impeller types

- Heating/Cooling: Jacketed or coil options; temperature control available

- Controls: Manual or PLC touch-screen panel with speed and temperature control

Applications

Ideal for cosmetics, skincare, food sauces, pharmaceuticals and specialty chemicals. The tank supports batch mixing, dissolution, dispersion and mild emulsification when paired with optional homogenizers or vacuum systems.

Why Choose FULUKE

FULUKE (Guangzhou Fuluke Cosmetic Equipment Co., Ltd.) brings over 30 years of industry experience. We deliver engineered mixing solutions that meet GMP and ISO standards and offer full customization, installation support and long-term service. Our focus on quality, sanitary design and process efficiency helps manufacturers scale safely and keep product batches consistent.

Contact FULUKE to discuss capacities, configurations and turnkey integration with your production line.

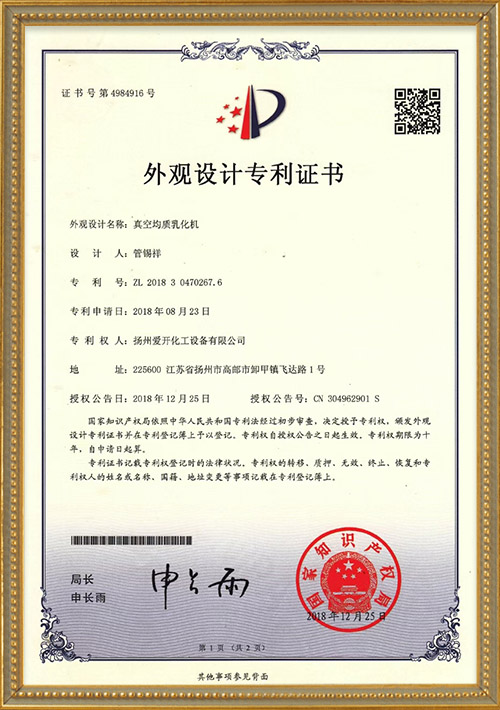

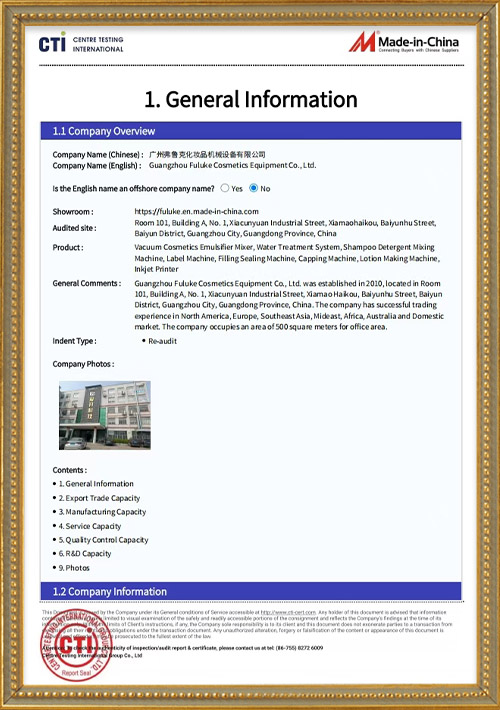

Certifications

Patent certificate

CTI

Certificate of conformity

Q&A

Can you customize the machine?

Of course, we provide customized services according to customer needs.

How often should the disperser and homogenizer be cleaned? How should they be cleaned properly?

Cleaning Frequency: Cleaning is required every time a material is changed to prevent cross-contamination. When the same material is used continuously, cleaning is recommended every 24 hours. Cleaning Method: Rinse with clean water or a suitable solvent (e.g., alcohol for oily materials, clean water for water-based materials). Remove stubborn stains with a soft brush. Avoid scratching with hard objects to avoid damage.

What sets FULUKE apart from other cosmetics machinery manufacturers?

What can you buy from us?

RO Water Treatment、Vacuum Emulsifying Machine、Homogenizer Mixing Tank、Filling and Capping、labeling Machine、Packing Machine、Storage Tank,etc.

If you have any questions about our goods or services, please feel free to contact us.

You May Also Like

Stainless Steel Mixer Liquid Mixing tank with Agitator Homogenizing Mixing tank Vacuum Sealed Mixer Machine

Flip Cover Multi-function Liquid Wash Mixing Tank Blender Liquid Detergent Mixer Homogenization Stirring Tank

Polypropylene PP Mixing Tank Anti-Corrosion Mixer Reaction Kettle with Agitator Chemical Mixing Vessel

Facebook

Instagram

YouTube