FULUKE Stainless Steel Mixing Tank — Hygienic Cosmetic Mixer

FULUKE Stainless Steel Mixing Tank

FULUKE (Guangzhou Fuluke Cosmetic Equipment Co., Ltd.) brings 30+ years of industry experience to a High Quality stainless steel mixing tank designed for cosmetics, food, pharmaceutical and chemical production. Engineered for hygiene, consistency and easy scale-up, this tank streamlines mixing, heating/cooling and cleaning while meeting GMP and ISO standards.

Key Features

- 316L stainless steel wetted parts for corrosion resistance and product safety

- Jacketed shell for precise heating and cooling control

- Efficient agitator designs (anchor, propeller, or high-shear options) for fast, uniform mixing

- Sanitary design with sloped bottom, drain valve and seamless welds for easy CIP (clean-in-place)

- Optional vacuum port and vacuum emulsifying mixer integration for air-free products and improved texture

- User-friendly PLC/HMI controls and automated recipes to ensure repeatable batches

Benefits & Advantages

Our stainless steel mixing tank reduces production variability and contamination risk while improving energy efficiency and throughput. The hygienic surface finish and compliance with GMP/ISO make it ideal for sensitive formulations such as creams, lotions and sauces. Custom sizes and automation options help manufacturers scale from R&D to full production without sacrificing product quality.

Applications

Designed for cosmetic mixing tanks, food-grade sauces, pharmaceutical intermediates and specialty chemicals, the FULUKE mixing tank supports a wide range of viscosities and processes — from gentle blending to high-shear emulsification when paired with our vacuum emulsifying mixers.

Why Choose FULUKE

Based in Guangzhou, FULUKE integrates engineering design, precision machining and global service. With turnkey production lines, onsite commissioning and long-term maintenance, we ensure your stainless steel mixing tank delivers reliable performance and regulatory compliance.

Contact FULUKE today to specify a custom stainless steel mixing tank or request a quote for integrated vacuum emulsifying mixer systems.

Picture Show

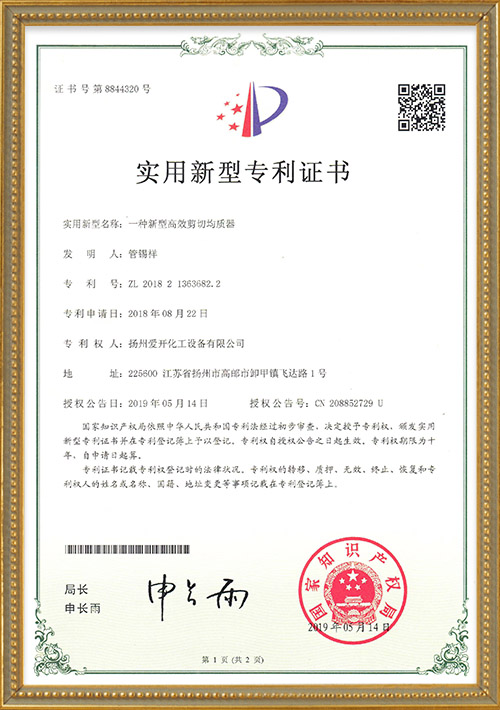

Certificate display

ISO certificate

Certificate of conformity

Patent certificate

FAQ

What can you buy from us?

RO Water Treatment、Vacuum Emulsifying Machine、Homogenizer Mixing Tank、Filling and Capping、labeling Machine、Packing Machine、Storage Tank,etc.

If the liquid is still turbid after filtration, what could be the cause?

Common causes include: ① Insufficient freezing (low temperature or too short a freezing time); ② Clogged filter element or overly large pore size; ③ Uneven material flow leading to insufficient localized condensation. Solution: Extend the freezing time, replace the 0.1μm precision filter element, check the pipes for blockage, and optimize flow control.

Can flip cover homogenizing mixing tank ensure hygienic safety when handling materials such as food and cosmetics?

Material Compliance: The equipment's pot, agitator, homogenizer, and other material-contacting components are all made of 316L stainless steel, which is corrosion-resistant and easy to clean, meeting food-grade and cosmetic-grade hygiene requirements.

Easy Cleaning: The open-top design allows direct access to corners within the pot, allowing for thorough cleaning by hand or with tools.

Operational Specifications: The equipment can be disinfected before use (e.g., hot water for food processing). After use, cleanup any remaining material promptly to avoid cross-contamination.

Who are we?

Our headquarters is located in Guangzhou, Guangdong, China, and our factory is located in Yangzhou, Jiangsu. Our products are sold all over the world. We have approximately 50 employees in our company and factory.

You May Also Like

Stainless Steel Mixer Liquid Mixing tank with Agitator Homogenizing Mixing tank Vacuum Sealed Mixer Machine

Facebook

Instagram

YouTube