FULUKE Emulsifying Machine — Vacuum Emulsifying Mixer for Cosmetics

FULUKE Emulsifying Machine — Reliable Mixing for Cosmetics

FULUKE (Guangzhou Fuluke Cosmetic Equipment Co., Ltd.) brings over 30 years of experience to a compact, powerful emulsifying machine designed for cosmetics, food, and pharmaceutical manufacturers. This vacuum emulsifying mixer simplifies production while ensuring consistent product quality and easier scale-up.

Key Advantages

- High-quality emulsification: Stable creams and lotions with a fine, uniform texture using advanced homogenizer technology.

- Vacuum mixing: Reduced bubbles and contamination for better appearance and shelf life.

- Efficient and fast: Shorter batch times and lower energy use to raise output and cut costs.

- GMP & ISO compliant: Built to international hygiene and safety standards for reliable manufacturing.

What Makes FULUKE Different

FULUKE combines engineering know-how, precision machining, and automation control to deliver turnkey solutions. Our emulsifying machines are designed for easy cleaning, repeatable batches, and flexible formulations. You get tailored systems—mixing tanks, homogenizers, and full packaging lines—backed by global service, installation, and long-term maintenance.

Applications and Suitability

This cosmetic emulsifying machine is ideal for manufacturers producing face creams, body lotions, hair care products, ointments, and food sauces. Whether you need a pilot unit or a full production line, FULUKE offers scalable solutions that keep product quality consistent as you grow.

Why Choose This Model?

- Customizable capacity and configuration to match your process.

- User-friendly controls and intelligent options for automated recipes.

- Robust after-sales support from a Guangzhou-based manufacturer with global reach.

Ready to improve your formulation quality and production efficiency? Visit https://www.fulukemix.com or email flk09@gzflk.com to request specifications, a quote, or a consultation on a complete emulsifying and packaging line.

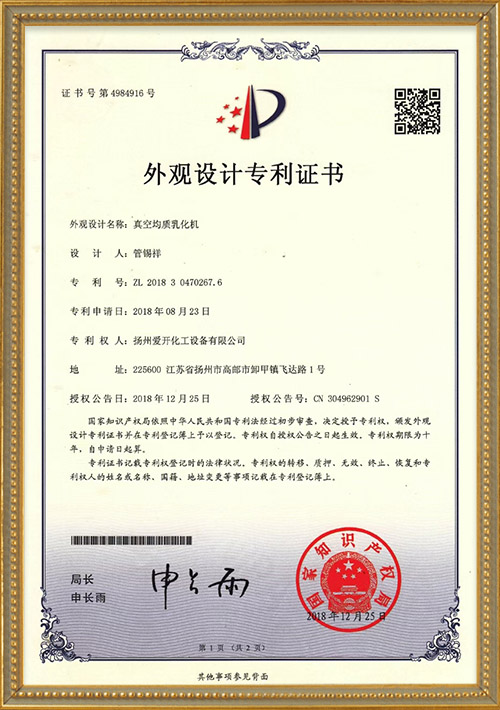

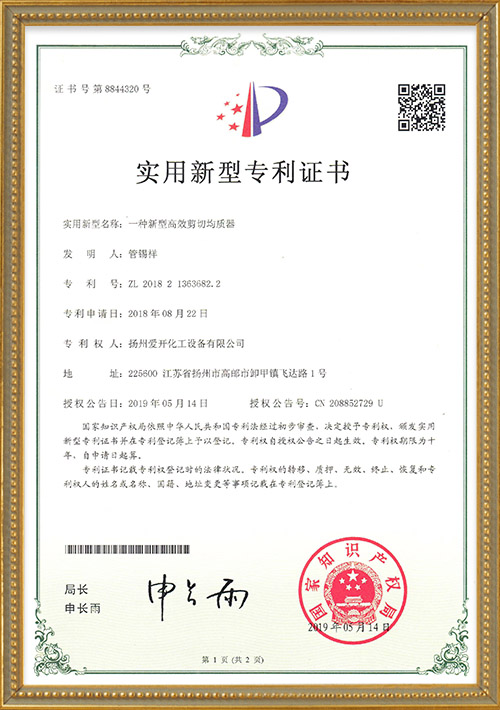

Certificate display

Patent certificate

Certificate of conformity

Patent certificate

Frequently Asked Questions

Who are we?

Our headquarters is located in Guangzhou, Guangdong, China, and our factory is located in Yangzhou, Jiangsu. Our products are sold all over the world. We have approximately 50 employees in our company and factory.

We want to fill products in multiple volumes (e.g., 5ml, 20ml, 50ml). Do we need to purchase multiple filling machines?

No, most facial mask filling machines support multiple volume adjustments. When purchasing, please confirm the machine's "volume adjustment range" (e.g., 5ml-50ml) to ensure it covers your desired specifications. Changing volumes simply requires modifying the fill volume parameters on the touchscreen.

Can the perfume filling machine accommodate perfume bottles of varying materials and shapes?

Yes. The machine utilizes adjustable mold positions and a PLC control system that allows for one-touch parameter switching, allowing it to accommodate a wide range of bottle shapes, including round, square, and special-shaped ones. The filling capacity range can be flexibly adjusted, and format changeovers take as little as 10 minutes, meeting diverse production needs.

How do I choose the right storage tank material?

Select based on the characteristics of the storage medium. For example, 316L stainless steel is preferred for food storage, while 304 or PE can be used for general water storage.

You May Also Like

Hydraulic lift Cosmetic Vacuum Homogenizer Emulsifying Mixer for Making Cream and Lotion Mayonnaise Mixing Machine

Facebook

Instagram

YouTube