FULUKE Emulsifying Machine — Vacuum Emulsifier for Cosmetics

Overview of the FULUKE Emulsifying Machine

FULUKE emulsifying machine is engineered for stable, high-quality mixing and emulsification of creams, lotions, gels, and sauces. Built by Guangzhou Fuluke Cosmetic Equipment Co., Ltd., with over 30 years of experience, this vacuum emulsifying mixer combines efficient mixing, powerful homogenization, and hygienic design to meet cosmetic, food, and pharmaceutical production needs.

Main Features

- Vacuum emulsifying mixer design reduces air entrapment and oxidation for longer product shelf life.

- High-shear homogenizer ensures uniform particle size and smooth texture.

- Stainless steel contact parts and sanitary seals meet GMP and ISO hygiene standards.

- Custom capacities and automation options support small labs to large production lines.

Benefits for Manufacturers

Using a FULUKE emulsifying machine improves batch consistency, reduces mixing time, and lowers energy use. The system is simple to operate and easy to clean, which minimizes downtime and helps maintain production safety. Our equipment integrates with filling and packaging lines for a seamless production flow.

Why Choose FULUKE

FULUKE is a trusted global manufacturer of cosmetic equipment. We combine engineering design, precision machining, and strict quality control to deliver reliable emulsifying solutions. Our vacuum emulsifying mixers comply with international hygiene standards and are backed by expert installation, commissioning, and long-term maintenance support.

Applications and Support

Ideal for creams, lotions, serums, sauces, and pharmaceutical creams. We offer tailored systems, process optimization, and intelligent control upgrades to meet your specific formula and production targets. Based in Guangzhou, China, FULUKE provides global service and technical guidance.

Learn more at https://www.fulukemix.com or contact us at flk09@gzflk.com to discuss a customized emulsifying machine solution.

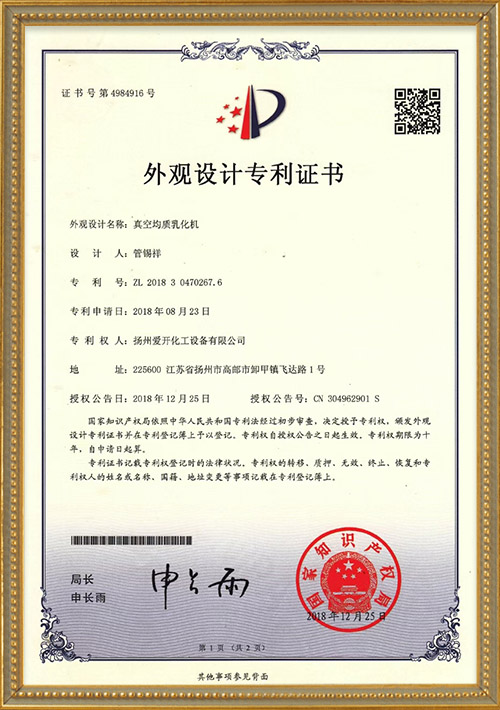

Qualification Certificate

Certificate of conformity

Certificate of conformity

Patent certificate

Q&A

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

What kind of heating method is there?

The heating methods include electric heating (heating medium is water or thermal oil) and steam heating. Generally, we recommend steam heating for pots larger than 500L.

How often should the disperser and homogenizer be cleaned? How should they be cleaned properly?

Cleaning Frequency: Cleaning is required every time a material is changed to prevent cross-contamination. When the same material is used continuously, cleaning is recommended every 24 hours. Cleaning Method: Rinse with clean water or a suitable solvent (e.g., alcohol for oily materials, clean water for water-based materials). Remove stubborn stains with a soft brush. Avoid scratching with hard objects to avoid damage.

What special safety features are required for equipment used to fill medical disinfectants (containing alcohol)?

An explosion-proof automatic filling machine is essential. Key safety features include: ① The motor and electrical components must be explosion-proof to prevent sparks from igniting alcohol vapors; ② The tanks and piping must be made of anti-static materials and grounded to prevent static electricity accumulation; The workshop must also be well-ventilated and equipped with an explosion-proof exhaust system.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

You May Also Like

Hydraulic lift Cosmetic Vacuum Homogenizer Emulsifying Mixer for Making Cream and Lotion Mayonnaise Mixing Machine

Fixed Type Vacuum Mixing Emulsifying Equipment for Cosmetic Cream Ointment Lotion Vacuum Homogenizer Mixer

Facebook

Instagram

YouTube