Ultimate Guide to Liquid Filling Machines in 2026: Types and Trends

A comprehensive 'Skyscraper' guide for industry professionals covering every aspect of liquid filling machines. From detailed comparisons of filling principles (piston, gravity, vacuum) to calculating Total Cost of Ownership (TCO) and navigating FDA regulations. This article explores cutting-edge trends like AI integration and sustainable packaging, positioning your production line for success in 2026.

- Introduction to Liquid Filling Machines: The Backbone of Modern Packaging

- Understanding the Different Types of Liquid Filling Machines by Filling Principle

- Gravity Filling Machines

- Piston Filling Machines

- Pump Filling Machines

- Overflow Filling Machines

- Vacuum Filling Machines

- Automation Levels: Manual to Fully Automatic Solutions

- Manual and Semi-Automatic Options

- Fully Automatic Liquid Filling Machines

- Key Factors for Choosing the Right Liquid Filling Machine

- 1. Product Viscosity and Characteristics

- 2. Regulatory Compliance (FDA & GMP)

- 3. Total Cost of Ownership (TCO)

- 4. Container Types and Flexibility

- Advanced Technologies: IoT, AI, and Robotics

- Installation, Operation, and Maintenance Best Practices

- Industry-Specific Applications

- Future Trends in Liquid Filling Technology (2026)

- Conclusion: Partnering for Precision

- Frequently Asked Questions

- What is the primary difference between volumetric and level liquid filling machines?

- How do I determine the right level of automation for my liquid filling needs?

- What is CIP (Clean-in-Place) and why is it important?

- Can one liquid filling machine handle multiple product viscosities?

- What are the typical maintenance requirements?

- How can I improve the accuracy of my liquid filling machine?

- What safety features should I look for?

- What is the role of IoT and AI in modern liquid filling machines?

- References

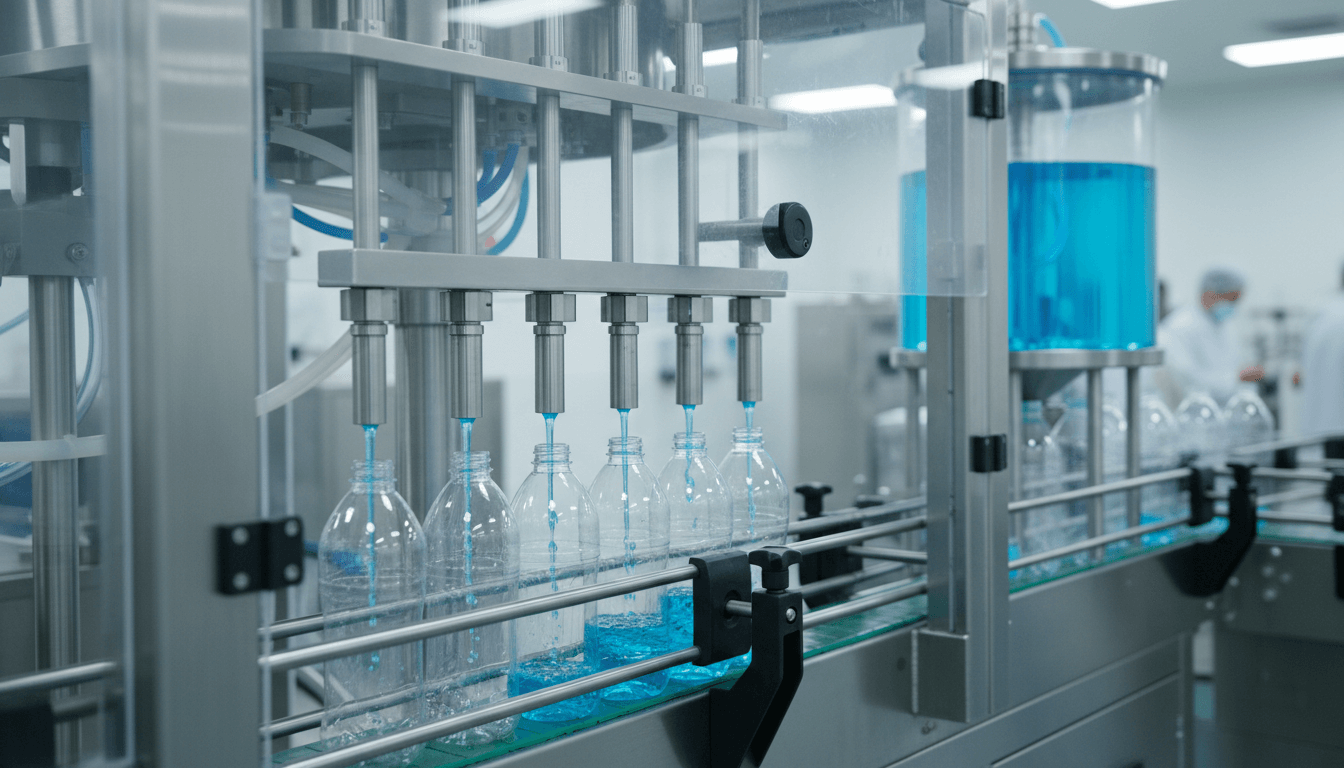

Introduction to Liquid Filling Machines: The Backbone of Modern Packaging

In the high-stakes world of manufacturing, the liquid filling machine is the heartbeat of the packaging line. Whether dispensing life-saving pharmaceuticals, premium spirits, or viscous cosmetic creams, these machines determine the speed, accuracy, and profitability of production. As we approach 2026, the global market for liquid packaging is evolving rapidly. According to Fortune Business Insights, the global liquid filling machines market size was valued at over USD 6.45 billion in 2024 and is projected to exceed USD 10 billion by 2032, driven by a surge in automation and strict regulatory demands.

For facility managers and production engineers, selecting the right equipment is no longer just about filling bottles; it is about integrating a solution that ensures compliance, minimizes waste, and adapts to Industry 4.0 standards. This guide serves as your definitive resource for understanding liquid filling machines, from core mechanics to future-proof strategies.

Understanding the Different Types of Liquid Filling Machines by Filling Principle

Selecting the correct filling machine begins with understanding the physics of your product. Viscosity, foaming characteristics, and particulate content dictate the engineering required.

Gravity Filling Machines

Gravity fillers are the workhorses for free-flowing, low-viscosity liquids like water, solvents, and thin beverages. How it works: A time-based or volumetric valve opens, allowing the liquid to flow into the container until a specific level is reached. They are cost-effective but struggle with viscous products.

Piston Filling Machines

For thick products like pastes, chunky sauces, or heavy creams, the viscous liquid filling machine often utilizes a piston mechanism.

· Mechanism: A piston draws product from the hopper into a cylinder and forces it into the container.

· Precision: As noted by industry experts, piston fillers offer exceptional volumetric accuracy, often within ±0.5%, making them ideal for high-value products.

Pump Filling Machines

These machines use different types of pumps to move product.

· Peristaltic Pump Fillers: Ideal for pharma and bio-tech. The fluid only touches the tubing, preventing cross-contamination.

· Gear & Lobe Pumps: Best for a wide range of viscosities, capable of handling particulates without crushing them.

Overflow Filling Machines

Commonly used in the cosmetic and beverage industries, these machines ensure a consistent visual fill level, regardless of minor variations in bottle interior volume. This is crucial for retail shelf appeal, especially for clear glass containers.

Vacuum Filling Machines

Primarily used for filling glass bottles with low-viscosity liquids (like perfume or wine). The machine creates a vacuum in the bottle, sucking fluid in. It is excellent for handling foamy liquids but unsuitable for plastic bottles that might collapse under pressure.

Automation Levels: Manual to Fully Automatic Solutions

Manual and Semi-Automatic Options

For startups or laboratories, a manual liquid filling machine offers a low barrier to entry. As production scales, semi-automatic liquid filling machines provide a balance, typically requiring an operator to place bottles but automating the fill cycle to reduce fatigue and improve consistency.

Fully Automatic Liquid Filling Machines

For high-speed environments, an automatic liquid filling machine is non-negotiable. These systems integrate conveyors, indexing drives, and PLC controls to fill hundreds of containers per minute.

· Inline vs. Rotary: Inline systems fill containers row-by-row and are easier to adjust for different shapes. Rotary systems, common in high-volume beverage plants, fill bottles as they travel on a circular turret, offering higher speeds but longer changeover times.

· Monobloc Systems: These compact units combine filling, capping, and labeling in a single chassis, saving valuable floor space.

Key Factors for Choosing the Right Liquid Filling Machine

1. Product Viscosity and Characteristics

A liquid bottle filling machine designed for water will fail catastrophically with honey. You must define if your product is a "free-flowing" liquid or requires a viscous liquid filler machine. Furthermore, consider if the liquid is corrosive (requiring titanium or specialty plastic parts) or flammable (requiring explosion-proof electrical systems).

2. Regulatory Compliance (FDA & GMP)

For pharmaceutical and food sectors, adherence to standards is mandatory.

· FDA 21 CFR Part 211: As stated in FDA regulations for pharmaceuticals, equipment must be designed for easy cleaning and sterilization to prevent contamination.

· ISO Standards: Packaging machinery safety is governed by standards like ISO 12100 and ISO 14121, ensuring operator protection.

3. Total Cost of Ownership (TCO)

Beyond the sticker price, calculate the TCO.

· Formula: TCO = Acquisition Cost + (Operating Costs + Maintenance + Downtime) - Resale Value.

· Energy Efficiency: Modern servo-driven auto liquid filling machine models consume less air and electricity than older pneumatic systems.

4. Container Types and Flexibility

Are you filling rigid glass, flexible pouches, or unstable plastic vials? While this guide focuses on rigid containers, some manufacturers also utilize a vertical form fill seal machine for liquid pouches, which requires a completely different feeding mechanism.

Advanced Technologies: IoT, AI, and Robotics

The "Smart Factory" is transforming liquid packaging.

· IoT & Connectivity: Modern liquid fill machine units are equipped with IoT sensors that monitor pump cycles, temperature, and motor load in real-time. According to a report by Apex Filling Systems, Industry 4.0 integration allows for predictive maintenance, alerting operators to wear before a breakdown occurs.

· AI & Machine Learning: AI algorithms can now auto-adjust fill timing based on changes in liquid viscosity due to temperature fluctuations, maintaining accuracy without human intervention.

· Vision Systems: Integrated cameras inspect bottles for defects or verify fill levels instantly, rejecting non-compliant units without slowing the line.

Installation, Operation, and Maintenance Best Practices

To ensure longevity for your automatic filling machine for liquid, a rigorous maintenance schedule is vital.

1. Site Prep: Ensure level flooring and stable utility connections (clean compressed air is critical).

2. Calibration: Regular weight checks are necessary to prevent "product giveaway."

3. Sanitization: Implement Clean-in-Place (CIP) protocols. For industries requiring high hygiene, such as those producing cosmetics, integrating a Vacuum Emulsifying machine upstream ensures the product entering the filler is perfectly mixed and air-free.

4. Troubleshooting: Common issues like "dripping nozzles" often stem from worn seals or incorrect suck-back settings.

Industry-Specific Applications

· Pharmaceuticals: Requires aseptic filling, often in a cleanroom environment using peristaltic or piston pumps with single-use pathways.

· Food & Beverage: Focuses on speed and hygiene (FDA CFR 21 compliance). Hot-fill technologies are used for juices and sauces to ensure shelf stability.

· Chemicals & Detergents: Corrosion resistance is key. For manufacturers aiming for the high quality of liquid detergent products, ensuring the filler does not introduce air bubbles (foaming) is as critical as the mixing process itself.

Future Trends in Liquid Filling Technology (2026)

Looking ahead, sustainability will drive innovation. We expect to see:

· Energy-Efficient Drives: Servo motors replacing pneumatics to reduce energy consumption by up to 30%.

· Flexible Manufacturing: Modular machines that can swap between a liquid filler machine module and a powder filler module on the same base.

· Blockchain Integration: For full traceability of the filling process, securing the supply chain against counterfeiting.

Conclusion: Partnering for Precision

investing in the right liquid filling machine is a strategic decision that impacts your bottom line for a decade or more. By prioritizing versatility, compliance, and smart technology, manufacturers can build a packaging line that is resilient and profitable. Whether you need a simple manual liquid filling machine or a high-speed auto liquid filling machine, the key is to define your requirements clearly and choose a partner who understands the engineering behind the liquid.

Frequently Asked Questions

What is the primary difference between volumetric and level liquid filling machines?

Volumetric fillers (like piston or flow meter types) deliver a precise measured volume of product, which is critical for compliance and cost control. Level fillers (like overflow fillers) fill every container to the same visual height, which is preferred for retail products in clear glass bottles where visual consistency is paramount, even if the internal bottle volume varies slightly.

How do I determine the right level of automation for my liquid filling needs?

You must analyze your required throughput (bottles per minute), budget, and labor availability. Startups often begin with semi-automatic machines (10-15 BPM). If your demand exceeds 30-40 BPM or requires consistent continuous operation, a fully automatic inline or rotary system is the better investment for long-term ROI.

What is CIP (Clean-in-Place) and why is it important?

CIP stands for Clean-in-Place. It is an automated method of cleaning the interior surfaces of pipes, vessels, process equipment, filters, and associated fittings without major disassembly. It is critical for liquid filling machines in food and pharma to prevent cross-contamination and ensure bacterial safety efficiently.

Can one liquid filling machine handle multiple product viscosities?

Yes, but with caveats. Pump fillers and piston fillers are versatile, but you may need to change nozzles or pump heads when switching from water-thin liquids to thick pastes. Machines specifically built for high viscosity (like heavy duty piston fillers) might be overkill and slow for thin liquids, while gravity fillers cannot handle thick products at all.

What are the typical maintenance requirements?

Routine maintenance includes daily flushing/cleaning of nozzles, weekly lubrication of moving parts (conveyors, gears), and monthly inspection of wear parts like O-rings, seals, and gaskets. predictive maintenance using IoT sensors is becoming the new standard to prevent unexpected downtime.

How can I improve the accuracy of my liquid filling machine?

Ensure your product supply is consistent (constant pressure/level in the hopper). Use servo-driven systems for precise control over the filling cycle. Regularly calibrate the machine using checkweighers and adjust the "suck-back" or nozzle closing timing to prevent drips.

What safety features should I look for?

Look for machines compliant with ISO 12100 safety standards. Essential features include polycarbonate safety guarding with interlocks (the machine stops if a door opens), emergency stop buttons accessible from multiple points, and explosion-proof ratings (ATEX or Class 1 Div 1) if filling flammable liquids.

What is the role of IoT and AI in modern liquid filling machines?

IoT allows for remote monitoring of machine health (motor temp, cycle counts) to predict failures. AI can analyze this data to optimize the filling speed vs. accuracy balance automatically, adapting to changes in liquid temperature or viscosity in real-time, significantly improving Overall Equipment Effectiveness (OEE).

References

· Fortune Business Insights: Liquid Filling Machines Market Size

· FDA: CFR - Code of Federal Regulations Title 21 Part 211

· Mordor Intelligence: Automatic Liquid Filling Machine Market Size & Share Analysis

RO water treatment: From equipment to treated water, building a robust defense line for safe and compliant drinking water.

FULUKE reverse osmosis equipment empowers the pharmaceutical and cosmetics industries to achieve compliant production.

The Ultimate Guide to Labeling Machines 2026: A Critical Component in Modern Packaging Operations

Top 15 Global Filling Machine Manufacturers: The Definitive Ranking for 2026

FAQs

How can customers contact FULUKE for inquiries or support?

Film Packaging Machine

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

Lift-type Homogenizing Disperser

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

Automatic Labeling Machine

What types of bottles can this automatic labeling machine label?

It can label flat, round, and square bottles on one side, two sides, or even all around.

Storage Tank

How can I extend the life of my storage tank?

Avoid storing media that are incompatible with the material to prevent corrosion.

Perform maintenance according to specifications and promptly repair damaged anti-corrosion coatings or seals.

When the tank is idle for an extended period, empty the media and protect it from moisture and dust.

Get in touch with FULUKE

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

You May Also Like

Fixed Type Vacuum Mixing Emulsifying Equipment for Cosmetic Cream Ointment Lotion Vacuum Homogenizer Mixer

Hydraulic lift Cosmetic Vacuum Homogenizer Emulsifying Mixer for Making Cream and Lotion Mayonnaise Mixing Machine

Automatic Tube Filling and Sealing Machine Toothpaste Sunscreen and Facial Cleanser Filling and Sealing Machine for Plastic and Aluminum-plastic Tube

Facebook

Instagram

YouTube