Professional vacuum emulsifiers are helping Vietnamese cosmetics companies achieve efficient production and collaboration.

This case study focuses on a successful collaboration with a renowned Vietnamese cosmetics company. This company, deeply rooted in the local beauty market, specializes in skincare and makeup products and has stringent requirements for the emulsification precision, stability, and safety of its production equipment. To meet their needs for high-efficiency mass production and improved product quality, we customized and supplied core production equipment, including vacuum emulsification machines, precisely tailored to the production of cosmetic creams and lotions. Throughout the collaboration, we provided detailed product manuals covering operation procedures, parameter adjustments, daily maintenance, and safety precautions, along with dedicated remote support to ensure the client's team quickly mastered the equipment operation. This collaboration not only ensured the smooth commissioning of the client's production line but also improved product emulsification uniformity through the superior performance of our equipment, helping the client optimize production efficiency and reduce losses. This laid a solid foundation for long-term cooperation and showcased our professional expertise in the field of beauty equipment.

In today's increasingly competitive beauty industry, the professionalism of production equipment directly determines product quality and market competitiveness. Vietnam, as a market with significant potential for beauty product consumption and production in Southeast Asia, has seen a continuous increase in demand for high-end production equipment from local companies. Our client in this collaboration is a high-quality cosmetics company deeply rooted in the Vietnamese market. Their products, tailored to the skin needs of local consumers, have a stable customer base. With expanding production capacity, the client urgently needed to replace outdated equipment to improve the emulsification effect and production efficiency of their core products such as creams and lotions. After extensive research and comparison, they ultimately chose to collaborate with us, purchasing key production equipment including vacuum emulsifiers.

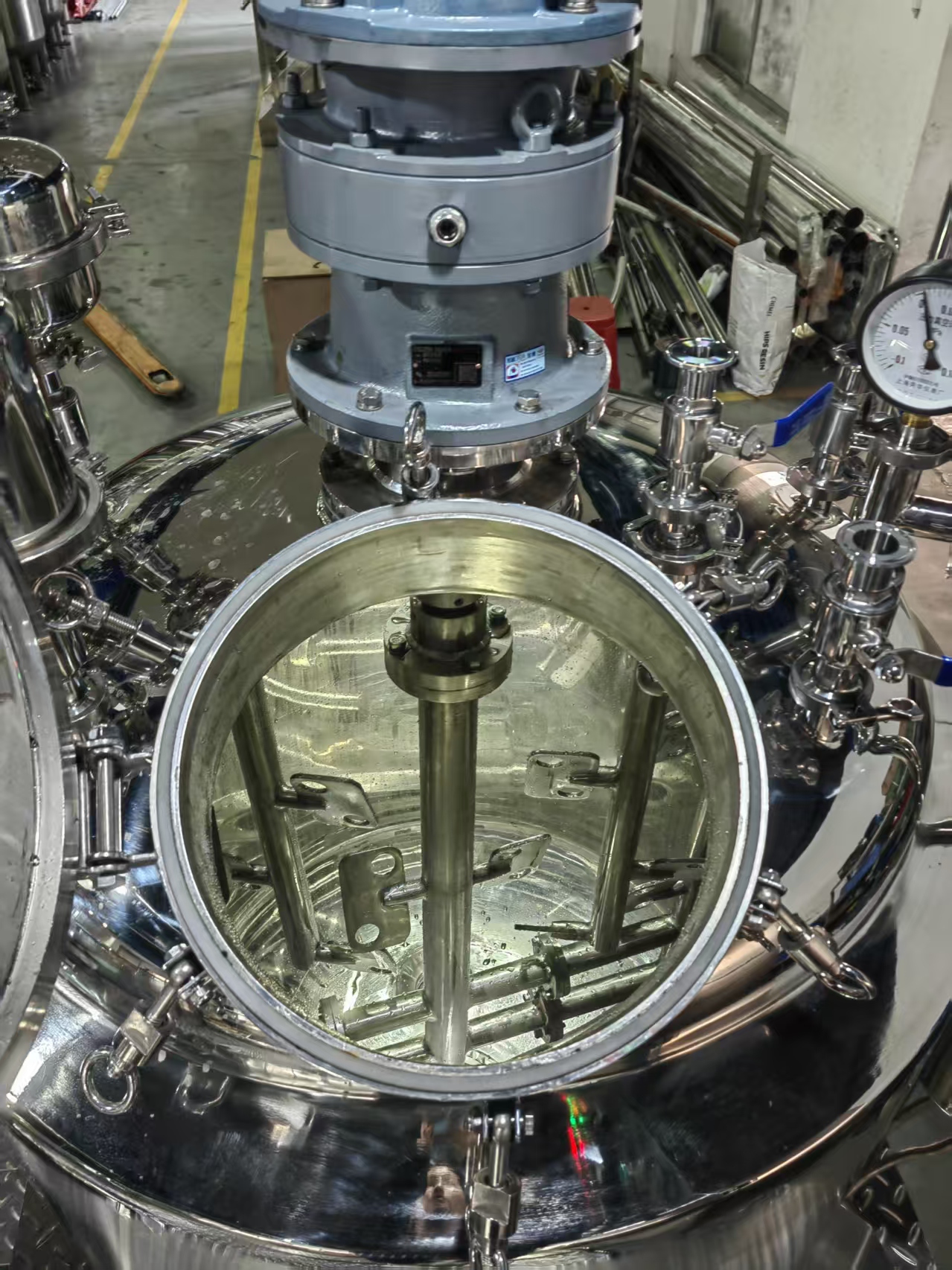

Based on our deep understanding of the production needs of the cosmetics industry and the specific characteristics of our client's products, we customized a vacuum emulsifying machine tailored to the properties of cosmetic raw materials. This equipment boasts high emulsification precision, stable operation, and low energy consumption, effectively preventing material oxidation and bubble formation, ensuring a fine and uniform product texture that meets the core requirements of cosmetics regarding skin feel. Considering the unique aspects of cross-border cooperation, we prepared a detailed product instruction manual in advance, clearly outlining procedures such as startup and commissioning, parameter settings, daily cleaning and maintenance, and troubleshooting common problems. This manual, accompanied by illustrative diagrams, ensures that personnel with varying levels of operational experience can quickly learn to use the equipment.

Following the successful implementation of the collaboration, our team provided remote technical support, promptly addressing any questions the client had regarding the instruction manual and equipment operation. We assisted them in optimizing production parameters to ensure the equipment was quickly integrated into their existing production line. After the equipment was put into use, the client's production efficiency increased by over 30%, the product emulsification success rate significantly improved, and material loss was greatly reduced, effectively lowering production costs. This collaboration not only provided the client with new momentum for capacity upgrades but also earned their high recognition through our professional products and meticulous service. This experience has provided us with valuable insights for expanding into the Southeast Asian beauty equipment market and laid a solid foundation for further collaboration and creating more value together. In the future, we will continue to focus on the needs of the beauty industry, providing higher-quality equipment and services to help more overseas companies achieve production upgrades.

You May Also Like

Fixed Type Vacuum Mixing Emulsifying Equipment for Cosmetic Cream Ointment Lotion Vacuum Homogenizer Mixer

The fixed vacuum emulsifier is an industrial device designed specifically for homogenizing and emulsifying high-viscosity materials. It utilizes a fixed installation structure and features a high-efficiency vacuum system, which rapidly removes air bubbles from materials within a closed environment, preventing oxidation and ensuring product smoothness and stability.

Equipped with a high-speed homogenizing head, it uses strong shear forces to micronize materials to a fine level, achieving uniform mixing of different ingredients and easily preparing products such as creams, lotions, and gels. Furthermore, the device integrates intelligent temperature control and wall scraping and stirring functions to precisely control process temperatures, eliminating material adhesion and dead corners. It meets the production needs of various industries, including cosmetics, pharmaceuticals, and food, and offers both efficiency and reliability.

Hydraulic lift Cosmetic Vacuum Homogenizer Emulsifying Mixer for Making Cream and Lotion Mayonnaise Mixing Machine

The vacuum emulsifier is an advanced device that integrates multiple functions, including mixing, emulsification, homogenization, heating, and cooling. It is widely used in the cosmetics, food, pharmaceutical, and chemical industries. Through its unique design and advanced technology, it can efficiently process a variety of materials in a vacuum environment, ensuring stable and consistent product quality.

Automatic Tube Filling and Sealing Machine Toothpaste Sunscreen and Facial Cleanser Filling and Sealing Machine for Plastic and Aluminum-plastic Tube

This automatic tube filling and sealing machine is suitable for automatic orientate eye marks, filling, sealing, date printing, and tail cutting of various plastic tubes and aluminum-plastic composite tubes. It is widely used in daily chemical, medical, food, and other industries. (For example, toothpaste, facial cleanser, sunscreen, etc.) Features: This machine uses touch screen and PLC control, automatic tube loading and positioning, and a heat phoenix heating system formed by imported fast and efficient heaters and high-stable flow needles.

It has a firm seal, fast speed, no damage to the seal surface, and a beautiful and neat seal. The machine can be equipped with a variety of filling heads of different specifications to meet the filling requirements of different viscosity, and is equipped with organic glass anti-seal.

Effective Automatic Facial Mask Filling Machine 2/6/8 Heads Facial Mask Filling and Sealing Machine

Facial mask filling machines are core equipment specifically designed for automated facial mask production, integrating automatic bag removal, essence filling, degassing and sealing, and coding output. They primarily enable precise filling of liquids (such as essences and nutrient solutions) into facial mask bags (mostly composite aluminum-plastic film bags) and seal the bags. They are a critical link between raw material processing and finished product packaging in industrialized facial mask mass production.

Their core value lies in improving production efficiency, ensuring filling accuracy and sealing quality, while reducing the risk of contamination from manual intervention, and meeting the cosmetics industry's stringent hygiene and compliance requirements.

Get in touch with FULUKE

If you have any comments or good suggestions, please leave us a message, later our professional staff will contact you as soon as possible.

Facebook

Instagram

YouTube