FULUKE Automatic Foundation Filling Machine

FULUKE Automatic Foundation Filling Machine

FULUKE’s Automatic Foundation Filling Machine is designed for cosmetic manufacturers who demand speed, accuracy, and hygiene. Ideal for liquid and cream foundations, this machine delivers consistent fills with minimal product loss and gentle handling to preserve formulation quality. Backed by FULUKE’s 30+ years in cosmetic equipment manufacturing, it integrates reliable mechanics, smart controls, and sanitary design for smooth production.

Key Benefits

- High Accuracy and Consistency: Precise dosing and stable output reduce giveaway and ensure every bottle or tube meets your quality standards.

- Gentle Handling: Engineered to minimize air incorporation and preserve texture and pigment dispersion—critical for foundations.

- Hygienic Design: Stainless steel contact parts, easy-to-clean surfaces, and CIP-friendly layouts meet GMP and international hygiene requirements.

- Flexible and Scalable: Easily adjustable for different viscosities, container shapes, and production speeds—suitable for startups and large-scale lines.

- User-Friendly Controls: PLC with touch-screen interface for recipe storage, quick changeovers, and simple operation.

Why Choose FULUKE

FULUKE (Guangzhou Fuluke Cosmetic Equipment Co., Ltd.) brings over three decades of expertise in mixing, emulsifying, and complete packaging lines. Our filling machines are engineered to integrate seamlessly with upstream emulsifiers and downstream sealing and labeling systems, offering turnkey solutions that improve efficiency and product consistency.

Applications and Support

Perfect for foundations, BB/CC creams, tinted moisturizers, and other liquid-to-semi-solid cosmetics. We offer customization, installation, commissioning, and long-term technical support to ensure your production runs reliably from day one.

Upgrade your filling process with FULUKE’s Automatic Foundation Filling Machine—efficient, accurate, and built for hygiene. Contact us for a tailored solution and a demo to see how it fits your production line.

Detailed display

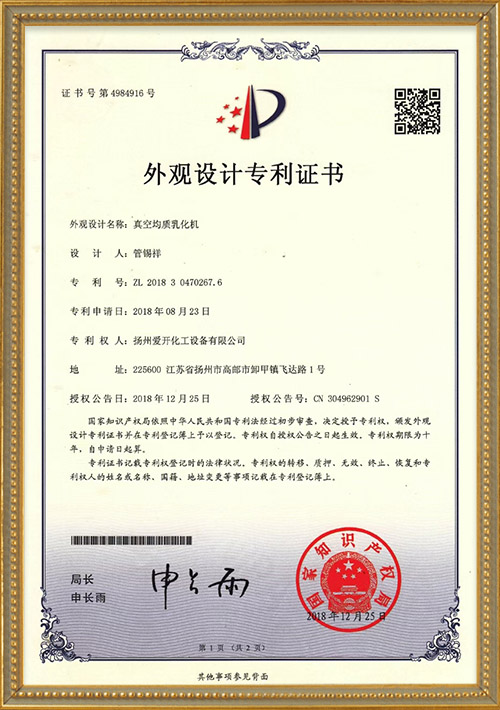

Qualification Certificate

CE certificate

Patent certificate

ISO certificate

FAQ

How often should the disperser and homogenizer be cleaned? How should they be cleaned properly?

Cleaning Frequency: Cleaning is required every time a material is changed to prevent cross-contamination. When the same material is used continuously, cleaning is recommended every 24 hours. Cleaning Method: Rinse with clean water or a suitable solvent (e.g., alcohol for oily materials, clean water for water-based materials). Remove stubborn stains with a soft brush. Avoid scratching with hard objects to avoid damage.

Can you make a design for us?

Yes, we can, we provide not only products, but also solutions and designs.

Is it possible not to configure the oil and water pot?

Of course, if you have other containers to pre-treat and heat the materials, then you only need to configure an emulsifying pot.

Can you customize the machine?

Of course, we provide customized services according to customer needs.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

You May Also Like

Automatic Filling Machine Quantitative Liquid Bottle Filling Machine High-precision cream and lotion filling machine

Effective Automatic Facial Mask Filling Machine 2/6/8 Heads Facial Mask Filling and Sealing Machine

Automatic Tube Filling and Sealing Machine Toothpaste Sunscreen and Facial Cleanser Filling and Sealing Machine for Plastic and Aluminum-plastic Tube

Facebook

Instagram

YouTube